When the Vruzend caps were first designed, the caps fit extremely tight on the cells. This allowed the caps to maintain a strong electrical connection even in heavy vibration environments. However, it also made it difficult to push on many caps together due to the stronger force required.

Starting with the V1.5 update, the Vruzend caps were redesigned to allow them to slide onto the battery cells more easily and make the assembly process go smoother. This has greatly expedited assembly, but it does mean the caps aren’t as vibration resistant as they used to be. In addition, each manufacturer of 18650 cells uses a slightly different diameter 18650 can, meaning different 18650 cells will fit slightly tighter or looser in the Vruzend caps. Panasonic cells are some of the narrowest cells, but some other cells can occasionally fit a bit looser, and vibrations can cause the cells to work their way back out of the caps due to the spring force over time.

But fear not! There are two easy ways to solve this and ensure that your cells stay firmly inside your Vruzend caps.

Method 1: sandwich plates

Sandwich plates are any type of rigid board or plate that goes on either side of your battery pack to compress the two sides together, like a sandwich. These can be plastic, wood, fiberglass, metal (but be careful of shorts) or any other material. Cutting boards are a commonly used material for sandwich plates as they are rigid and can often be found at the dollar store.

These plates can be held together in a number of ways, but zip ties or through bolts are the two most common. If your pack is narrower, such as 2-3 cells wide, you can probably get away with a thinner and less rigid sandwich plate material, as it doesn’t need to resist much bending in the center because the pack isn’t very wide. For wider packs, a very rigid material is helpful to ensure the center caps are also being held down, or a bolt through the center of the pack between caps can also reinforce the center of the sandwich plates (be very careful if drilling through the pack that your drill bit is exactly in the corner between 4 caps, and use as narrow a drill bit as possible to avoid touching any battery cells. It’s best to perform and drilling when the caps are not on the cells.

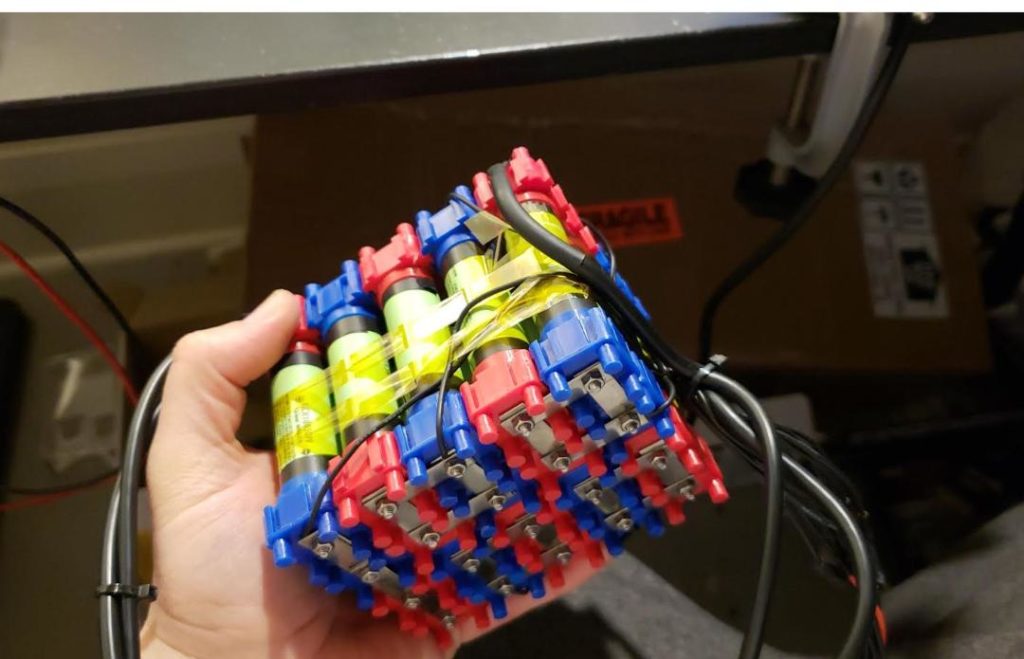

The picture below shows an example of aluminum sandwich plates bolted onto a rather large battery.

If your battery is very thin, such as 2-3 cells wide, you can often get away without using any sandwich plates at all, just zip ties wrapped around the pack every couple of cells. This will keep your caps pressed down onto cells even during vibration.

Method 2: cell wrapping

The other way to help resist your cells being pushed out of the caps during vibration is by wrapping your cells at the ends with either electrical tape or heat shrink to increase the diameter of the cell slightly. This will help the caps fit more tightly on the cells.

The wrapping method is especially useful with Panasonic cells which are already somewhat narrower than most other 18650 cells.

Both methods, either sandwich plates or cell wrapping, can be very effective at reinforcing the strong connection between the cells and terminal caps, and we recommend one of the two methods be used for V1.5 and later caps if the battery pack will be used in an environment that experiences vibrations.